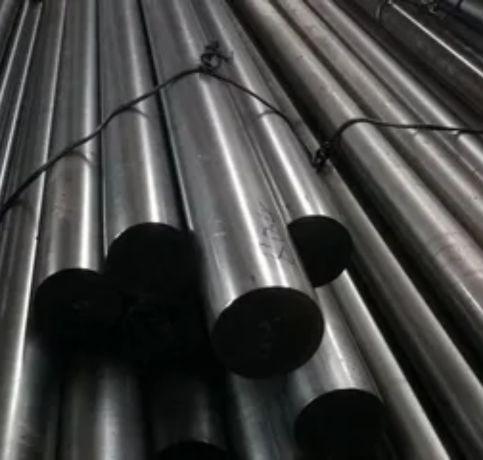

Marcus Metals is one of the prominent manufacturer and supplier of high-quality C45 Round Bars within Midland, UK. Using a commitment to perfection, we ensure that premium C45 Round Bars are distributed with superior strength, durability and versatility in application throughout industry. Our products are designed to exceed the latest standards in industries so our delivered results are reliable and will meet performance expectations in critical applications. As a trusted supplier, Marcus Metals offers tailored solutions to meet the unique needs of our clients while ensuring prompt delivery and exceptional service.

C45 Round Bar is a medium carbon steel with a composition of approximately 0.45% carbon, 0.60-0.90% manganese and trace amounts of other elements. It offers excellent mechanical properties, including a tensile strength of 600-850 MPa and yield strength of 350-500 MPa. C45 is highly machinable, heat treatable, and provides good wear resistance, making it suitable for components such as shafts, gears and structural parts. Its cost-effectiveness, high strength, and versatility make it ideal for engineering and manufacturing applications.

|

Variant |

Cast |

Weldability |

C % |

Si % |

Mn % |

P % |

S % |

Cr % |

Ni % |

Mo % |

V % |

Ti % |

Cu % |

Al % |

DI % |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SB8673 |

CC |

CEV 0.71max |

Min |

0.46 |

0.15 |

0.70 |

– |

0.020 |

0.25 |

0.10 |

– |

– |

– |

– |

0.020 |

1.70 |

|

Pcm 0.55max |

Max |

0.49 |

0.35 |

0.80 |

0.020 |

0.035 |

0.30 |

0.20 |

– |

– |

– |

0.25 |

0.040 |

2.00 |

||

|

SB1672 |

CC |

CEV 0.72max |

Min |

0.42 |

0.10 |

0.50 |

– |

0.020 |

– |

– |

– |

– |

– |

– |

– |

1.10 |

|

Pcm 0.55max |

Max |

0.50 |

0.40 |

0.90 |

0.045 |

0.045 |

0.40 |

0.40 |

0.10 |

– |

– |

– |

– |

1.80 |

||

|

SB1671 |

CC |

CEV 0.58max |

Min |

0.42 |

0.15 |

0.50 |

– |

0.035 |

– |

– |

– |

– |

– |

– |

– |

1.20 |

|

Pcm 0.51max |

Max |

0.50 |

0.40 |

0.80 |

0.045 |

0.050 |

– |

– |

– |

– |

– |

– |

– |

1.60 |

||

|

5081, Imatra 4 M |

CC |

CEV 0.72max |

Min |

0.42 |

0.10 |

0.50 |

– |

0.020 |

– |

– |

– |

– |

– |

– |

– |

1.10 |

|

Pcm 0.55max |

Max |

0.50 |

0.40 |

0.90 |

0.030 |

0.035 |

0.40 |

0.40 |

0.10 |

– |

– |

– |

– |

1.80 |

||

|

5155 |

CC |

CEV 0.72max |

Min |

0.44 |

0.10 |

0.50 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

1.10 |

|

Pcm 0.55max |

Max |

0.49 |

0.40 |

0.80 |

0.030 |

0.025 |

0.40 |

0.40 |

0.10 |

– |

– |

– |

– |

1.80 |

||

|

047A |

IC |

CEV 0.76max |

Min |

0.46 |

0.15 |

0.50 |

– |

0.020 |

– |

– |

– |

– |

– |

– |

0.015 |

– |

|

Pcm 0.6max |

Max |

0.50 |

0.40 |

0.80 |

0.030 |

0.030 |

0.25 |

0.25 |

0.10 |

0.100 |

0.005 |

0.25 |

0.030 |

– |

||

|

C45 EN 10083-2:2006 |

Std |

CEV 0.68max |

Min |

0.42 |

– |

0.50 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

Pcm 0.55max |

Max |

0.50 |

0.40 |

0.80 |

0.045 |

0.045 |

0.40 |

0.40 |

– |

– |

– |

– |

– |

– |

||

|

C45R EN10083-2:2006 |

Std |

CEV 0.65max |

Min |

0.42 |

– |

0.50 |

– |

0.020 |

– |

– |

– |

– |

– |

– |

– |

– |

|

Pcm 0.53max |

Max |

0.50 |

0.40 |

0.80 |

0.030 |

0.040 |

0.40 |

0.40 |

– |

– |

– |

– |

– |

– |

||

|

C45E EN 10083-2:2006 |

Std |

CEV 0.71max |

Min |

0.42 |

– |

0.50 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

Pcm 0.55max |

Max |

0.50 |

0.40 |

0.80 |

0.030 |

0.035 |

0.40 |

0.10 |

– |

– |

– |

– |

– |

– |

|

Diameter d (mm) |

Thickness t (mm) |

0.2 % proof stress (N/mm2) |

Tensile strength (N/mm2) |

Elongation A5 (%) |

Reduction Z (%) |

|

<16 |

<8 |

min. 490 |

700-850 |

min. 14 |

min. 35 |

|

<17-40 |

<8<=20 |

min. 430 |

650-800 |

min. 16 |

min. 40 |

|

<41-100 |

<20<=60 |

min. 370 |

630-780 |

min. 17 |

min. 45 |

USA | Germany | China | Japan | France | England | Italy | Poland | ISO | Austria | Sweden | Spain |

ASTM/AISI/ UNS/SAE | DIN,WN-r | GB | JIS | AFNOR | BS | UNI | PN | ISO | ONORM | SS | UNE |

1045 G10450 | C45/Ck45/1.1191/C45 | 45# | S45C | C45E Ck45 | C40E 080M466 | 1660 |

Yes, C45 Round Bar can be recycled and repurposed without losing its essential properties.

C45 Round Bar does not have a specific pressure rating, as it is primarily used for mechanical and structural applications, not pressure-bearing components.

Yes, C45 Round Bar may require corrosion protection coatings when exposed to harsh environmental conditions to prevent rust and degradation.

C45 Round Bar is widely used in engineering and manufacturing due to its excellent strength and machinability. Common applications include the shaft, gears, axles, bolts, and other mechanical parts that require medium carbon content. This material is also used for making parts in the automotive, construction industries along with other heavy machinery. The C45 Round Bar is extensively used in producing wear-resistant parts like crankshafts and connecting rods.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Marcus Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Midland, UK

Copyright 2024 Marcus Metals. All rights reserved